Gland Packing Seal

Gland Packing Seal

GLAND SEALING

Gland sealing is the standard form of sealing adopted for many slurry pump applications due to it’s relative robustness, gradual failure mode and ease of maintenance.

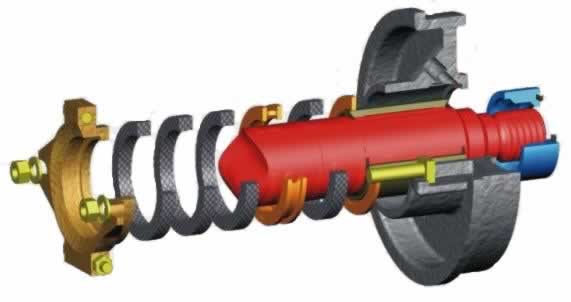

ANATOMY OF A GLAND SEAL

A gland seal is comprised of a chamber (Stuffing Box) which houses stationary sealing components such as Lantern Rings, Neck Rings and Gland Packing. The chamber allows for flushing water to be feed into the sealing area through a feed hole. Passing through the centre of the chamber is a shaft which may have a sacrificial wear sleeve which rotates against the stationary packing in the sealing chamber or stuffing box. Pressure is applied between the packing and shaft sleeve through a gland follower which when tightened compresses the packing, this forms a sealing line between the sleeve and the packing, between the pressure in the pump and atmosphere outside the pump.

Naturally this friction creates heat for which the the purpose of flushing water is to do what it says, flush and cool the sealing line between the stationary and rotating parts. Within a slurry pump which can pump not only solids laden product but also acidic or alkaline solutions allowances need to be made to reduce not only the effects of friction between the sleeve and packing but also corrosion and erosion.

FAILURE MODES OF GLAND SEALS

There are 3 main forms of attack on gland seals in slurry pumps that lead to sealing failure. These can be either individual or combined effects.

1. Corrosion – Generally caused by a hyper saline or chemical environment with incorrect materials selection. Apart from direct chemical or oxidisation effects on materials crystallization around sealing surfaces can compound failure through parts erosion.

2. Erosion / Wear – Normally caused due to contamination of the sealing chamber by slurry being pumped through inadequate flow and pressure of sealing water, can also be caused through fluid crystallization or through excessive force applied between sealing surfaces through over tightening of the gland follower.

3. Friction – Normally caused through over zealous gland adjustment to achieve near zero leakage. However this then causes a breakdown of the flushing water function in cooling of the gland. All gland sealed pumps are designed to leak and should be allowed a slow trickle or fast drip of flushing water from them to facilitate cooling and flushing or the sealing line.

The failure cycle of a gland seal is generally progressive due to the robustness of the design which has inherent redundancy, gland seal failure it is rarely instantaneous. Energy is the underlying form of failure, physics tells us that energy follows the path of least resistance. Within a gland that is stressed due to any combination of the above conditions energy is being transferred and dissipated across the sealing components, this energy can be in the form of chemical, potential, kinetic etc. associated with either the fluids or solids in the chamber. So naturally the fluids / solids will seek to release or transfer their energy to the weakest component in the chamber being the packing. This is exactly what a gland seal is designed to do, the packing is the main sacrificial element in the chamber and as such is changed out more often than the other components.

However over time gland packing has been enhanced to the point that special material such as Kevlar, Carbon Fibres and Teflon have been incorporated into it’s design, this has resulted in packing being much more stable and able to resist wear or to dissipate the energy into other areas of the sealing chamber, namely the secondary sacrificial element being the shaft sleeve.

Shaft sleeves along with lantern and neck rings are probably the second most changed out components of a gland sealing system. historically sleeves have been made out of alloys that are harder wearing than the gland packing so that they last longer. But as packing has evolved in strength and design with resultant longer lifespan sleeves have either been changed with packing cycles or enhanced through new materials, coating systems or a combination of both. Enhanced sleeves which offer hard coatings for wear resistance can then outlast new generation packing and offer enhanced service life across the sealing line. However many coating systems have their own inherent design flaws and weaknesses which if not supported by sufficient feed of flushing and cooling water can lead to accelerated failure of the gland seal.

For more information on failure of coated sleeves please refer to our CIS Sleeve page.

FAILURE MODE REDUCTION

Measures to reduce the effects of gland seal failure modes include.

1. Sealing Configuration – Ensuring that you have selected the right sealing configuration for duty and process conditions. On this point there are many aftermarket products available that offer enhancements to pump sealing over original design, each offering needs to be assessed on it’s claims and merits taking into account not only the pump duty but process conditions.

2. Flushing Water – Ensuring that the gland has the correct arrangement of parts with sufficient clean flushing water at the right pressure and flow. Over 90% of sealing problems can be traced back to insufficient feed of clean flushing water at the correct pressure, with correct gland adjustment.

3. Materials Selection – Selection of the right materials to suit the duty conditions of the pump and the availability of flushing water.

Stuffing Box – In chemical duties an inert material needs to be used however most chemically inert materials are not hard wearing so a compromise material may need to be selected that gives a balance of wear life and chemical resistance. For wearing duties harder materials can be used but you will need to be mindful that the harder the material then generally the lower it’s mechanical strength and subsequent pressure capacity. For Chemical and hard wearing applications you need a material that is wear and chemically resistant. For this environment Slurrytech have developed the SB-WRC (Stuffing Box – Wear Resistant Carbide face), this seal is constructed from a chemically resistant alloy Stuffing Box with a hard wear face coating of WRC (Wear Resistant Compound) exposed to the slurry side of the chamber.

Shaft Sleeves – Sealing sleeves rotate with the pump shaft against stationary rings of packing in the stuffing box. Basic material grades of sleeves are in hardened stainless and are generally very robust, pumps running these sleeves normally have gradual failures of the sealing assembly. New generation sleeves are available with a variety of hardened coatings and application processes for these. Most coated sleeves suffer from a disassociation of material properties between the substrate and the coating which can lead to rapid failure of the gland seal. Slurrytech CIS sleeves are designed to offer a harder wearing surface that is infused into the substrate to avoid traditional failure modes of most coating systems. Please see CIS Sleeve page. for further information on our sleeves.

Gland Packing – Today’s modern gland packing comes in more varieties, wraps and material combinations than has ever been available in the past. the key rule with packing is to ensure that you match the packing for the chemical, wear and gland materials being used as well as taking into consideration gland water availability and pressures. All these factors effect how well not only the packing but the sleeve and other components will hold up in duty conditions. Unfortunately there is no one type suits all conditions design of packing available.

At Slurrytech have designed our own general range of packing which consists of Kevlar woven corners for strength, braided Teflon walls for reduction of friction and a bound graphite core for lubrication and solids take up.

All glands in slurry conditions will suffer from solids contamination over time, we have designed our packing with this in mind so that it has the capacity to take up and absorb contaminants rather than bind them up between the sleeve and the packing. Our grade of packing works equally well for alloy or ceramic coated shaft sleeves and is suitable for a wide range of pH levels and pump pressures.

Winclan factory

We enjoy strong technological power, excellent equipments and perfect inspection instruments, so we could provide you high-quality products with competitive price.

About us/Our principle is fine quality, in time consignment, reasonable price.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu