-

WQ潜水泵

WQ full head multistage sewage submersible pump (hereinafter referred to as electric pump), which is composed of pump, seal and motor. The motor is located in the upper part of the electric pump, which is a three-phase asynchronous motor; the pump is located in the lower part of the electric pump, which is a flow channel impeller-volute structure. The mechanical seal is used between the pump and the motor, and the "O" shaped oil-resistant rubber sealing ring is used as the static seal to ensure the reliability of the electric pump. The pump adopts special sand control structure to ensure the reliability and service life of the electric pump; the lower part of the pump is equipped with guide bearings, so when the water level is low, the electric pump can be placed and operated horizontally (or tilted) according to the actual situation, but the motor is not allowed to run out of the water or invert the electric pump.

When the rated lift is more than 100m, the electric pump is equipped with a silencing check valve to avoid damage to the electric pump due to the phenomenon of water hammer during shutdown. The user can also adjust the installation angle of the bend according to the actual use situation, in order to facilitate the installation of the pipeline.

The rotor shaft of electric pump is made of stainless steel to ensure that the shaft has more reliable mechanical strength, which can effectively improve the wear resistance and corrosion resistance of the shaft, and is also convenient for the maintenance and disassembly of the impeller.

This series of electric pumps are widely used in industry, agriculture, mining, construction, municipal environmental protection and other places. They can pump liquids containing solid particles or soft solids such as short fiber, paper chips, sediment and so on, such as mud water, ash water, domestic wastewater, sewage, fecal urine and so on. They are ideal water conservancy equipment for agricultural drainage and irrigation, river pond silting and site construction, but they are not suitable for use in situations with explosion-proof requirements.

-

Slurry Pump Cover plate

Slurry Pump Cover plate-013 The pump body is an important part of the pump and plays a key role in the normal and safe operation of the pump. Therefore, the quality requirements of the pump cover casting are high and need to meet the requirements of hydrostatic test. According to the working pressure, the pump cover is made of nodular cast iron, vertically split and connected with bolts, which can support the pump. Connected with the bracket, the pump outlet can rotate in eight ... -

Slurry Pump Frame Plate

Pump cover is an important part of the pump, which plays a key role in the normal and safe operation of the pump. Therefore, the pump cover casting quality requirements are higher, the need to meet the requirements of hydraulic test pump cover according to the working pressure, the pump cover is made of nodular cast iron, vertical middle open, connected with bolts, supporting the pump. Slurry Pump Frame Plate-032 Slurry Pump... -

Throatbush-083-A05

Slurry Pump Throat Bush Material: 1.A05 is a wear resistant white iron that offers excellent performance under erosiveconditions.The alloy can be effectively used in a wide range of slurry types.The high wear resistance of alloy A05 is provided by the presence of hard carbides within its micro-structure. Alloy A05 is particularly suited to applications where mild corrosion resistance,as well as erosion resistance is required. 2.A49 is suitable for low pH corrosion duties , where erosi... -

Slurry Pump Expeller-028-A05

Slurry Pump Expeller-028-A05 The hydrodynamic seal of the auxiliary impeller refers to the installation of an open impeller in the opposite direction coaxially near the back of the back cover of the impeller of the pump. When the pump is working, the auxiliary impeller rotates with the main shaft of the pump, and the liquid in the auxiliary impeller also rotates together. The rotating liquid will generate an outward centrifugal force. On the one hand, this centrifugal force resists th... -

FramePlatelLinerlnsert-4041HS1-A05

1.A05 is a wear resistant white iron that offers excellent performance under erosiveconditions.The alloy can be effectively used in a wide range of slurry types.The high wear resistance of alloy A05 is provided by the presence of hard carbides within its micro-structure. Alloy A05 is particularly suited to applications where mild corrosion resistance,as well as erosion resistance is required. 2.A49 is suitable for low pH corrosion duties , where erosive wear is also a problem . The al... -

Rubber pump accessories-R55

Wear resistance: long service life; the test result of wear value is generally 0.03-0.20 cm3/1.6km; it is more than 0.3-2 times that of the alloy sheath; Corrosion resistance: It is resistant to corrosion by various acids, alkalis, salts and seawater; it uses rubber-lined pumps, and the overflow part is lined with synthetic rubber. It is suitable for PH0.5-14 containing suspended particles, temperature within 100 °C, and concentration below 70% Sulfuric acid, less than 30% saline-alka... -

Stuffing Box-078JM

Stuffing Box-078JM Slurry Pump Stuffing Box interchangeable with AH Series Slurry Pump Code The stuffing box of slurry pump is an indispensable part in the use of slurry pump. As a sealing component, it has the advantages of simple structure, easy manufacture, easy installation and easy maintenance, so it is widely used. 1. Reduce the leakage of pressure water on the drainage side; 2. Prevent air from entering the pump body at the suction side to ensure the normal operation of the pump... -

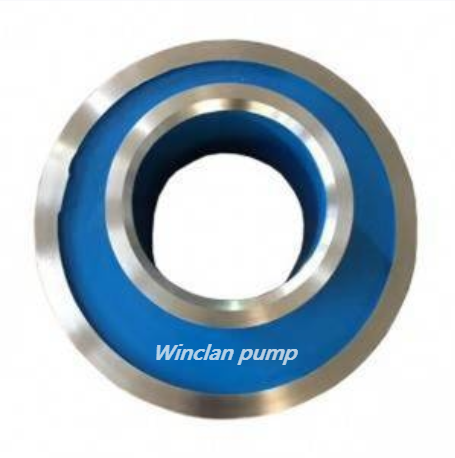

Gland Packing Seal-078

Gland Packing Seal GLAND SEALING Gland sealing is the standard form of sealing adopted for many slurry pump applications due to it’s relative robustness, gradual failure mode and ease of maintenance. ANATOMY OF A GLAND SEAL A gland seal is comprised of a chamber (Stuffing Box) which houses stationary sealing components such as Lantern Rings, Neck Rings and Gland Packing. The chamber allows for flushing water to be feed into the sealing area through a feed hole. Passin... -

Ni Hard White Cast Irons

Ni Hard White Cast Irons Ni Hard is the trade name for a group of nickel chromium alloyed white cast irons possessing outstanding resistance to abrasion. Ni Hard types 1 and 2 have proved an economic replacement for white cast iron under most conditions of wear-resisting service and for carbon and 12% manganese steels for wear resistance under conditions of moderate impact. Increased wear and impact resistance are possible with Ni Hard 4. Differences in service properties of Ni ... -

Slurry pump Impeller-147-S42

Slurry pump Impeller-147-S42 Wear resistance: long service life; the test result of wear value is generally 0.03-0.20 cm3/1.6km; it is more than 0.3-2 times that of the alloy sheath; Winclan Slurry Pump Impeller are 100% interchangeable with AH, HH, SP and G series slurry pumps. Winclan factory We enjoy strong technological power, excellent equipments and perfect inspection instruments, so we could provide you high-quality products with competitive price. Contact Us ... -

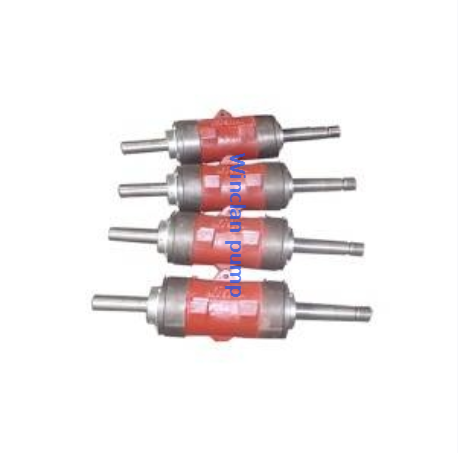

Bearing Assembly-005

Slurry Pump Bearing Assembly-005 The role of the slurry pump rotor assembly: Bearing assemblies are used to connect the slurry pump and motor components to form a complete working system It is used to transmit power, bear the force under the working state and the corresponding axial force Make sure that the impeller rotates and performs work on the same axis. Choose to use according to different work performance, in order to achieve the purpose of effective...